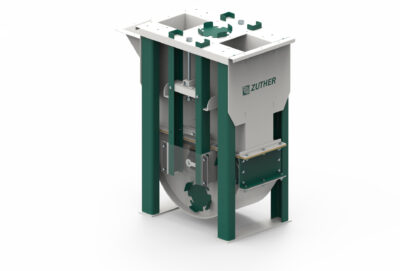

New generation bucket elevator

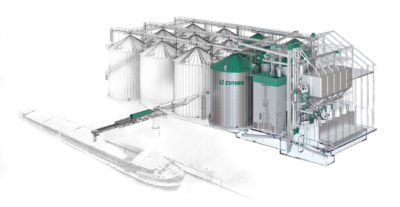

Within the 100 years of company history, we have always strived to optimise our products in order to constantly increase our quality. The daily cooperation with our customers from different industries, the multitude of implemented projects and our decades of experience form the foundation for our product development. The new generation elevator of the ELY series convinces not only with its quality and a multitude of possible options, but also with an attractive price/performance ratio.

Standardised modular design

Despite its standardised modular design, the new series provides a high degree of flexibility and offers diverse application possibilities in a wide range of industries. In addition, we offer our customers and partners attractive delivery times and convince them with a tried and tested, reliable and high-performance system.

Optimised design

To meet maximum quality requirements, all elevators are equipped only with high-quality components. High performance and reliable conveying of your bulk material is the prerequisite for a worthwhile investment.

The modified design allows a free-standing installation of the elevators and thus avoids the use of cost-intensive support structures such as steel towers or similar. Taking into account the optimal use of materials and sheet thicknesses, the design nevertheless convinces with its proven and robust construction.

A multitude of possible equipment options allows the use in various fields of application and industries. The series can be supplied galvanised, painted or made of stainless steel. In addition to the standard provisions for material conveying that is as free of residues as possible, additional options such as the telescopic elevator foot offer all the prerequisites for a food-safe design.

New generation of bucket elevators

In addition to efficient aspiration of the product flow, the optional aspiration nozzle also offers the advantage that a deflector plate creates a separate aspiration chamber which prevents bulk material from being aspirated. Basically, however, the series is virtually dust- and waterproof.

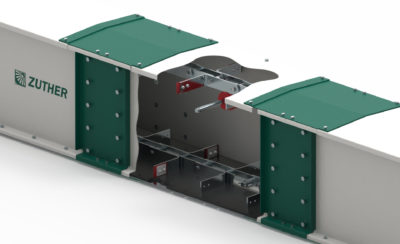

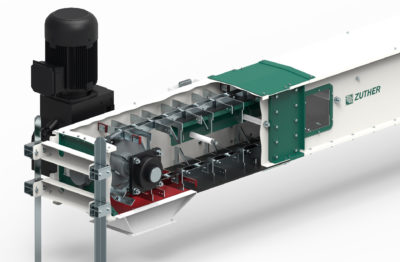

The entire design has been constructed to be maintenance-friendly and thus offers a large number of maintenance hatches. In the elevator head, the split head cover, in addition to two other hatches, offers optimal maintenance access. Optional clamping sets and the special design allow the entire drive unit to be replaced in the shortest possible time. The freely accessible clamping hatch is located above the elevator foot, making assembly, maintenance or repair work particularly convenient.

Energy-efficient & reliable

The drive technology is designed to achieve the highest possible energy efficiency without sacrificing long and reliable service life.

A high running performance is also guaranteed by the optimised wear lining (Kryptane ®/PE1000). Zuther installs a lining over the entire ejection parabola and not only on the ceiling of the head. The inlet noses are also provided with a three-sided wear lining. The design ensures quiet, safe operation and guarantees the lowest possible wear. For example, the buckets are prevented from hitting the shaft by avoiding belt misalignment and by dimensioning the shaft accordingly.

With a performance range of 20-800 tons per hour (0.75 t/m³), we cover a wide range in the standard. Let us convince you of our elevators and trust us and our slogan: Quality by tradition!

Advantages

- High reliability and operating performance

- Free-standing installation possible (up to 50 metres)

- Can be used universally and for various bulk materials

- High discharge heights and conveying capacities possible

- High-quality components installed (belt, buckets, drives, bearings etc.)

- Elevator belt temperature-resistant up to 180°C, resistant to oil and grease

- Very maintenance-friendly, numerous optimised maintenance accesses

- Maintenance-friendly design, e.g. easy removal of the entire drive unit in one piece possible

- Low-wear design, avoidance of bucket impact due to optimised dimensions

- Design optimised for assembly and commissioning

- Can also be used in buildings without any problems due to low noise emission

- Dust- and waterproof construction

- Numerous options (wear lining, aspiration etc.)

- Rubberised drive drum incl. clamping sets from ELY08 onwards

- Food-safe design possible

- Designed according to the explosion protection directive ATEX 94/9EG on request

- Energy-efficient design of the drives