Screw conveyor for grain and plastic

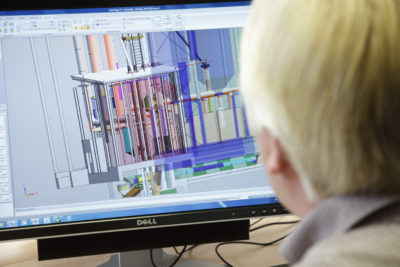

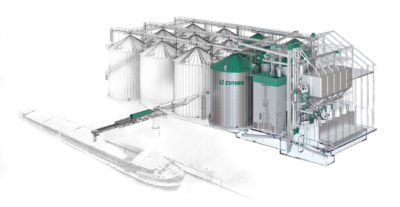

Zuther screw conveyors are used worldwide in a wide variety of industries. By combining our experience with state-of-the-art machinery, we are able to provide screw conveyors of reliable quality.

screw conveyors: the right solution for every requirement

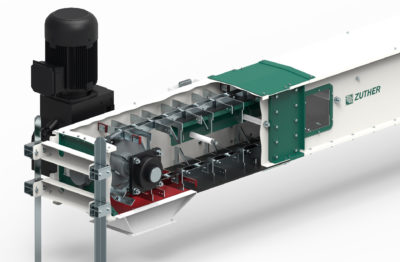

Screw conveyors are suitable for many different applications. Whether used as connecting, discharging, dosing, stuffing or dewatering screw conveyors, our technology ensures reliable operation.

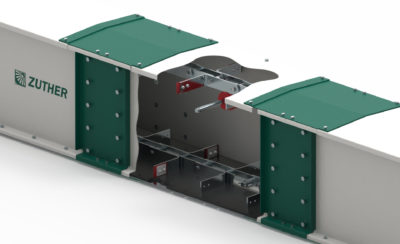

Particularly noteworthy here is the highly effective sealing of the screw tube by the Zuther labyrinth seal. It prevents the material being conveyed from escaping on the screw shaft, which could otherwise lead to contamination and damage to the bearings.

The equipment options include many different drive variations, equipment with an intermediate bearing for longer conveying distances, special bearings for high-temperature environments or extreme gradients, screw blades made of wear-resistant materials for abrasive bulk solids, and much more. Thus every screw conveyor from Zuther is equipped to meet even the most difficult requirements.

Features of Zuther's screw conveyor

- Compact modular system

- Dust-tight and odor-tight

- Specially protected bearings for long service life

- Easy maintenance for low maintenance costs

- Can be used even in the most difficult environments

- With open screw trough can also be used as discharge system

- Available painted, galvanized or in stainless steel

- For numerous bulk solids

- Suitable for many different applications

- Capacities of up to 250 t/h

- various designs - trough, pipe or extraction screw

- special bearings for high temperature environments

- Screw flights made of wear-resistant materials

- Zuther labyrinth seal