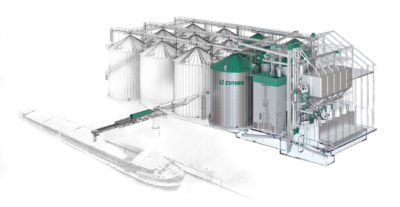

Gutter dedusting system reduces dust generation during the acceptance process

From the very first point at which delivered grain arrives at a plant, a side effect occurs that you want to be rid of as quickly as possible: dust. It makes perfect sense to deal with the problem as soon as it arises, before the further propagation of dust-burdened air makes countermeasures impossible.

Dust removal from the receiving gutter

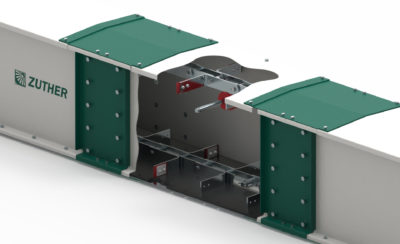

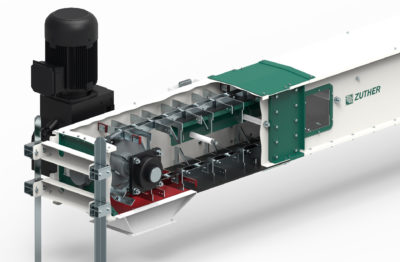

A receiving pit constitutes a relatively large area that must be aspirated. Thus specially adapted systems are required to efficiently dedust large areas of this type. The dedusting systems from Zuther are especially developed for this purpose. Thanks to their modular design, they can be perfectly adapted to new constructions as well as to existing pits. Even if the pit is overfilled, functionality of the extraction wall is not impaired.

The concept reduces pressure losses in the extraction wall to a minimum. A dust lock is not necessary. As a result of this mode of operation, separate transport of the accumulating dust is not necessary. The entire system is very easy to master, both during installation and maintenance.

Features of Zuther's gutter dedusting system

- Receiving dedusting units for grain pits

- No dust lock necessary

- Low pressure losses

- Automatic, programmable controller

- Automatic return of the separated dust, i.e. transport is unnecessary

- Simple and inexpensive installation