Windsifter Vortex: Bulk material and grain cleaning

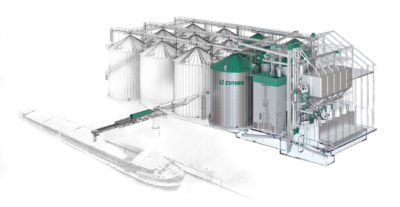

The VORTEX grain cleaner is the logical response to the requirement for treating bulk material with such high-capacity, speed, and cost-efficiency that additional steps in the processing chain can be carried out. For grain crops, these are mainly placement in storage, preparation for drying, and quality improvement when removing from storage.

Sustainable thanks to recirculation system

Environmentally friendly thanks to the integrated recirculation system with recirculation air separator, which produces only small amounts of exhaust air. The exhaust air is fed into a material separator with integrated filter system to ensure dust emission values of < 20 mg. For agricultural operations, a cyclone separator is sufficient for this purpose.

VORTEX – the reliable grain precleaner

Due to the compact and proven design of the grain cleaner, the machine convinces with its reliability and is ideally suited as a precleaner at your grain intake.

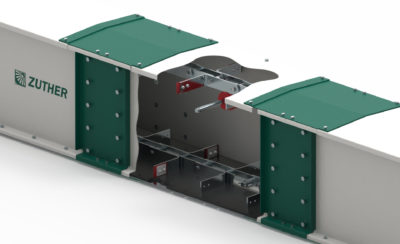

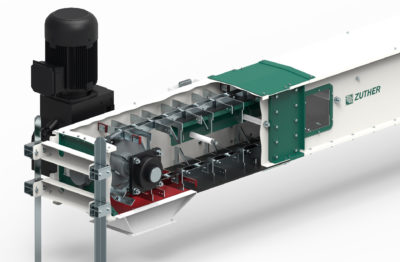

The Vortex is an air classifier that combines three important sorting components in a single machine with minimal spatial requirements. The maintenance-free rotational distribution of bulk material with the ingeniously simple ascending classifier geometry and the effective compact dust separator-fan combination cannot be found in this clearly arranged cylindrical design in any other solution. This results in a significant advantage in already existing plants to accommodate the VORTEX cost-efficiently and quickly.

Features of the Vortex grain cleaner

- Excellent cleaning performance - optimal precleaner

- Throughput capacity 80 - 250 t/h

- Compact design, small installation dimensions

- Environmentally-friendly thanks to air circulation system

- Very good price/performance ratio

- Easy operation, remote controllable

- Wear-resistant liner in the intake area

- Low exhaust air volumes

- Easy maintenance thanks to segmented design