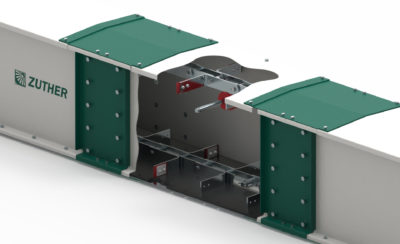

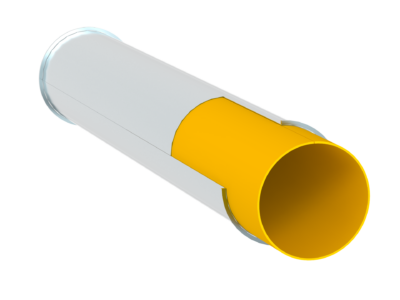

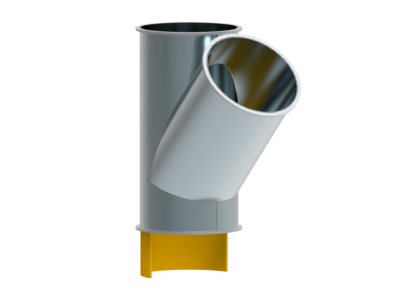

Wear resistant linings significantly increases the service life of pipes up to maintenance

Even materials as hard as steel are subject to wear under constant load. This cannot be prevented, however it can be circumvented. Instead of exposing the steel to direct contact with the bulk material, an additional wear-resistant liner is installed. The materials used are specially designed for wear resistance. Thus the interval until maintenance is required can be significantly increased. If the wear-resistant liner has reached the end of its service life, the complete component needs no longer be replaced, but rather only the wear-resistant liner must be replaced, which of course saves costs. Whether a complete lining or only the wear zones, which can be delimited, must be equipped with the supplemental layer depends on the component and its use.

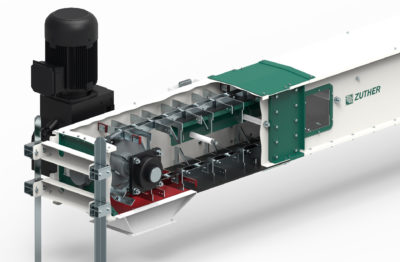

Wear resistant linings for your conveyor technology

Zuther uses a full range of extremely wear-resistant materials. It extends from high-tech polyethylene and polyurethane-based plastics to alloyed special steels, and armored steels. In this regard, selection of the materials used is highly dependent on the area of application. The additional costs for fitting with a wear-resistant liner are more than compensated through the extended service life and the reduced consequential costs.

Features of Zuther's wear lining

- Four times longer service life

- Wear-resistant liner for pipe system

- Many years of experience in handling

- Various materials available in different thicknesses

- Installation often possible at a later date

- Replacement can be carried out without great effort