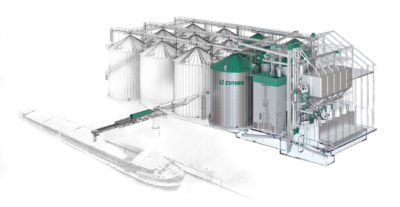

Air filter systems for modern grain plants

The legal requirements for handling dust-burdened air are becoming increasingly stricter. Consequently, the question of the right filter system becomes increasingly important.

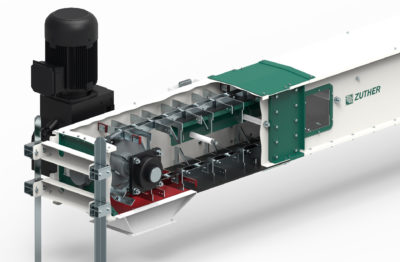

Modern grain plants, even of larger capacity, are usually planned in such a way that most of the conveying equipment is concentrated in one place. This factor can be exploited in the context of dust disposal. In this scenario, the conveyors are not dedusted by multiple point filters. Instead, a large filter system is installed to extract the dust-burdened air out of the conveyors via a network of aspiration lines, and separate it. The separated dust can then either be returned to the bulk material or disposed of as part of a chaff load.

A central dedusting system is a cost-effective solution for plants

Because the aspiration air causes virtually no wear, the pipeline can be made of a extremely thin-walled material, which under normal circumstances keeps the costs of the pipeline extremely low. Thus a central dedusting function can become a more cost-effective alternative even for a comparatively small plant.

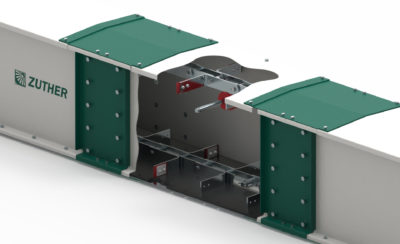

The filter surface area of the nozzle filter can be adapted to the requirements of every system.

As it is designed for continuous operation, automatic self-cleaning of the filter hoses takes place in parallel with filter operation. In this process a section of the filter hoses is blown out with compressed air, while the rest of the filter continues working. The cleanliness values of the exhaust air that are achieved are well below the legally permissible limit values.

Features of Zuther's dedusting system

- Nozzle filters with automatic compressed air dedusting

- Automatic, programmable controller

- Dust emissions in accordance with the 4th German Federal Immissions Control Act

- Cost-effective aspiration lines