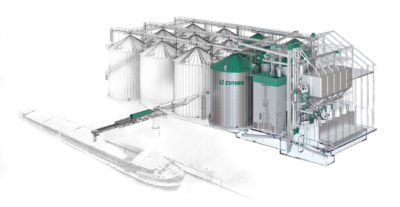

Conveyor belts for grain: high conveying capacity and long distances

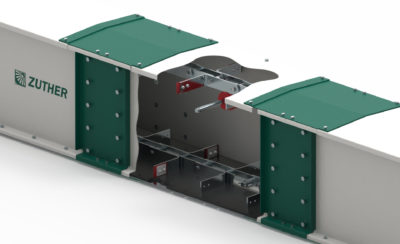

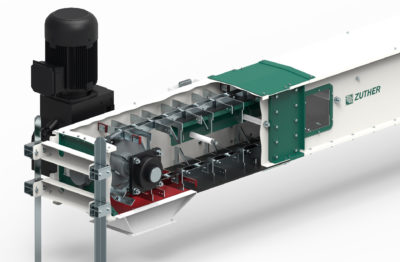

Belt conveyor are often used where high reliability is required. The Zuther company has two different systems in its program that more than meet this requirement: Conveyor belts with sliding belt and troughed conveyor belts with idler construction.

The troughed belt conveyors allow a very large capacity range of up to 1,000 t/h and bridgeable distances of well over 150 meters. The idler stations are very high quality, low maintenance and require low maintenance costs. Our conveyor belts are characterized by their reliability and universal application range.

Our conveyors also have the ability to handle many different bulk materials. Whether grain, wood chips, minerals, stones & soils or fertilizer: we find the best solution for every requirement.

- Very high conveying performance possible

- For various bulk materials: such as grain or coarse-grained bulk materials

- Suitable for unpacked food with BGA approval

- optional hood cover possible

- Suitable for sensitive, abrasive materials to be conveyed

- Good price-performance ratio, thanks to modular system

- Compact and lightweight

- Very low operating costs and maintenance effort

- Suitable for long distances - up to 150 meters