Quality by tradition - for generations

100 Years Zuther – Quality by Tradition!

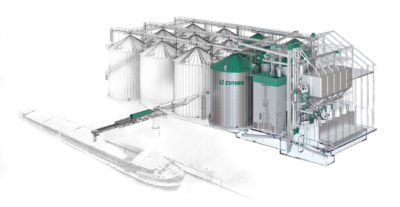

Today Zuther is one of the leading suppliers of bulk material technology!

Zuther technology proves itself today worldwide and across industries under the most difficult operating conditions. In the anniversary year 2021 the company succeeded in reaching another milestone. The granary of the world could be opened up as a sales area. From now on, Zuther technology will also be sold and used in the Ukraine, Russia, Moldova and Kazakhstan.

Also the continuation in the meanwhile fourth generation was secured by the entry of the two sons, of the managing owner Andreas Zuther, Jannik and Jonas Zuther, in 2014 and 2019 respectively.

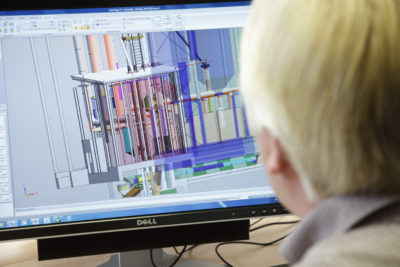

Zuther has developed into a modern industrial company that stands out from the rest by combining tradition and modernity. As a medium-sized family business, Zuther not only has state-of-the-art manufacturing, but is also one of the leaders in the industry in the field of digitalization. In addition to a newly introduced IT system, Zuther was also involved in the development of digital products for its customers – the sFIX maintenance and servicing software was created.

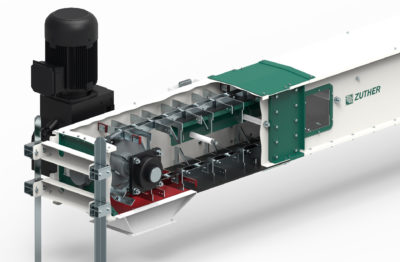

In recent years, Zuther has developed into one of the established suppliers of bulk solids technology. With great commitment, Zuther was able to win further markets for itself. Due to the high quality of the products, it was possible to gain market shares in the field of stones and soils and in the industry. Today Zuther operates internationally and in many countries. Always committed to the slogan “Quality by Tradition”.

Since 2014, Andreas Zuther took over the entire management and successfully leads the fortunes of the company.

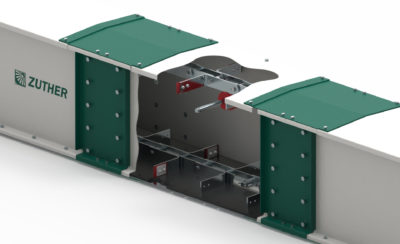

Due to a highly qualified team of employees, a modern production and the sum of our experience of almost 100 years, company Zuther developed to one of the leading suppliers in the field of bulk material technology. Due to the increasing demand, the production capacities were extended by two large production halls. Furthermore, investments were constantly made in the machinery. In the meantime, Zuther no longer operates only in the national market, but has also found international sales areas.

In the 70’s and 80’s, the manufacturing area was modernized by using new machines and expanding the manufacturing premises, and the product range was extended to include special machine construction and bulk handling for other products. The technical area was also extended, so that also with this know-how the delivery of turnkey silo and handling plants for various bulk materials was possible.

In 1988, Mr. Horst Zuther’s sons, Michael and Andreas Zuther, joined the company. Thus the continuity of the family business was secured and the production capacity was again expanded by the construction of a further production hall with the most modern production technology, equipment of the administration with IT, as well as computer-aided drawing technology and CNC-controlled machines, so that the technical know-how, reliability, quality and price-performance ratio could be further optimized and the competitiveness constantly expanded.

As more and more small and medium-sized mills were shut down in the course of the 1960s, the company had to look for another sales market and decided to focus on the field of grain storage and silo equipment. Efficient conveying technology and grain cleaning machines were developed for this sector, as well as the necessary dust removal technology for the grain silo facilities. In the course of the new technology and growing sales, it became necessary to expand metal processing by closing down the sawmill and constructing a new building for metal processing instead.

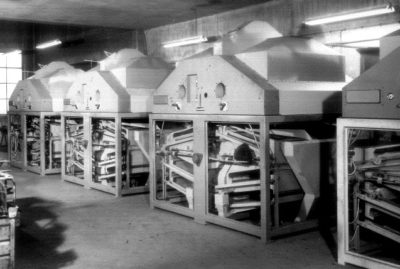

At the beginning of the 1950s, the first cleaning and processing machines for grain were developed. The machines selected sheaves, wafers, seeds, burnt balls and light grains from grain. The outputs were around 2 tons per hour. The machines were made of the finest mahogany.

In 1949, the company then moved with some employees and families to Neu Tramm in the Lüchow-Dannenberg district and set up a hall for manufacturing and administration.

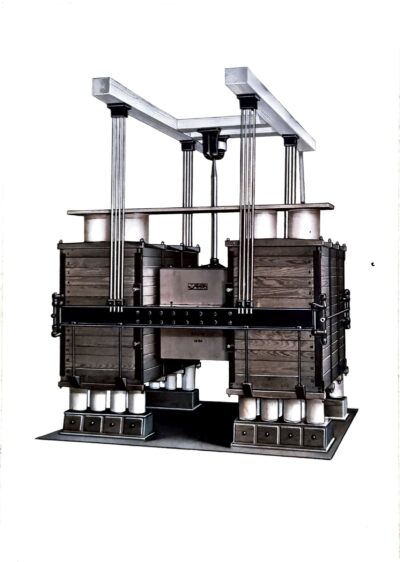

With the new premises, equipped for woodworking and metalworking, as well as a roll grinding and corrugating machine for reconditioning milling rolls, the company was now in a position to significantly expand its product range for milling machines. At this time, Mr. Horst Zuther, Karl’s son, also joined the company.

After the end of the war, Karl Zuther began to carry out repairs in small mills from Flensburg-Mürwik, together with his sons Alfred and Hans Zuther and a box of organized tools. The family lost their property during the war and started all over again – with courage, hope and entrepreneurial instinct. The business developed slowly; premises were rented and machines were purchased, and with the increase of employees, milling machines such as semolina and haze cleaning machines, sifters and flour mixing machines were produced again. The company developed and looked for larger premises and a better located plant site.

On October 10, 1921, the company Karl Zuther, Mühlen- und Speicherbau was founded by master miller and millwright Karl Zuther in Meseritz.

The company with its own workshop and about 10-15 employees dealt with the modernization and re-equipment of small and medium-sized mills.