Point filter for modern bulk material plants

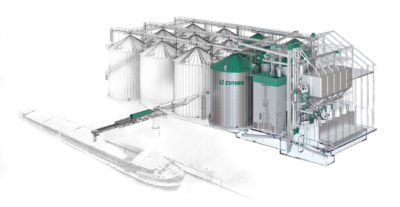

There are situations where connecting a conveyor to a central dedusting system can no longer be implemented in an economically viable manner. Especially in modern large-scale plants, too many aspiration pipelines might have to be laid for this purpose, which automatically leads to the problem of pressure drop in the aspiration system. Also it is not always intended for the extracted dust to be collected and disposed of centrally. Often, the dust should rather remain in the conveyed material.

Point filter: To keep the dust-burdened air in the conveyed material

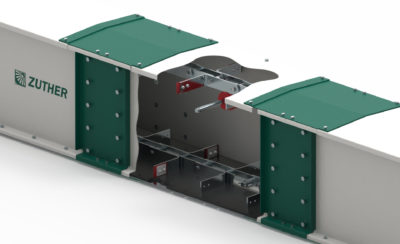

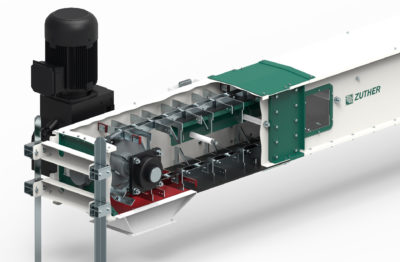

In this case it is more effective to use point filters directly on the conveyors. They filter dust-burdened air out of the conveyors and return the dust cake that accumulates through automatic dedusting back into the conveyors. Thus weight loss of the conveyed material does not occur due to aspiration.

Zuther supplies point filters for a wide range of applications. Horizontal trough chain conveyors, as well as vertical elevators can be equipped with point filters. Each point filter, after being supplied with power, works fully autonomously.

Features of point filters by Zuther

- Direct aspiration at the conveying device

- No cost-intensive aspiration lines necessary

- No weight reduction of the conveyed goods