Telescopic elevator foot for more cleanliness – delivery to Brazil

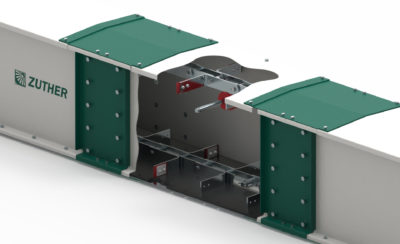

Increased residual clearance due to telescopic elevator foot

any applications require particularly residue-free transport. Major challenges arise in vertical conveying, for example by belt elevators. Zuther developed the telescopic elevator foot in order to provide customers with a foot that is free of residues. This variant is used in particular in industry or in the food processing industry.

As well as in a current project:

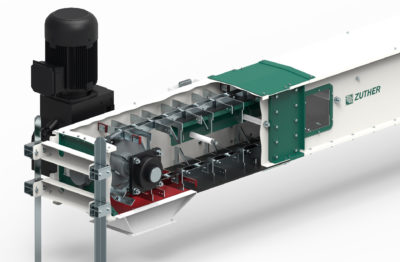

For an industrial plant in Brazil, we supplied a belt elevator for a capacity of 50 t/h for the processing of clay. The eleven meter high elevator was also equipped with a Zuther-Tele foot and successfully put into operation. In addition, the foot was equipped with a residual slide and large maintenance hatches, thus ensuring easy cleaning and maintenance of the foot.

In the following, we would like to point out the advantages of the residue-free variant:

No corners for the deposit of the bulk material in the foot

Re-scooping of the buckets is guaranteed

Optionally with a slide for emptying the residue

Constant bucket distance to the bottom

During belt tensioning the elevator foot travels with the bucket

Large maintenance hatches

The foot is available galvanized, painted and in stainless steel. To ensure a safe application only the highest quality components are used.

The advantages

- No deposition of residues possible

- Telescopic design

- Constant bucket spacing – even during belt tensioning

- Large maintenance hatches

- High reliability

- Durable construction

- 50-800 t/h conveying capacity

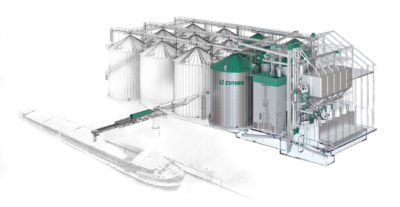

Our services and products at a glance