In 2020, we were allowed to develop and build a new ship loading incl. solution concept. The project posed very special challenges.

The demands on the new ship loading were very high and required a great deal of commitment from our team.

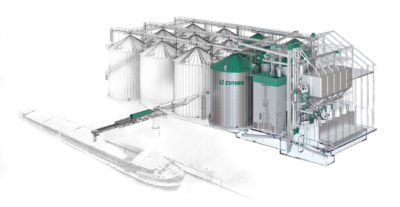

The installation situation was probably one of the biggest challenges. Not only were the structurally limited dimensions between the quay wall and the machine house very tight, but the ship loader was also not allowed to interfere with operations on the two existing rail tracks and the truck lane.

In addition, it had to be ensured that an existing harbor crane could move freely in the harbor. For this reason, the ship loading had to be able to swivel 90° to the left and right and to pass over the existing rail tracks and rails of the harbor crane.

The new loading system also had to have a high loading capacity and enable a 1000-ton ship to be fully loaded without having to “haul” it again.

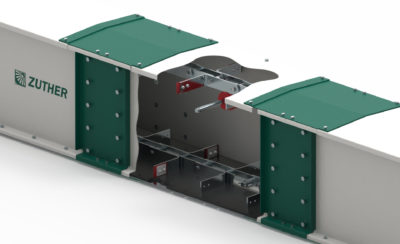

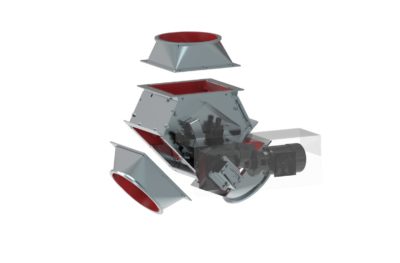

The loading system was a customized solution. In addition to the project management, which also included the coordination with the port company, the ship loading was newly developed and constructed based on our modular system.

- Tight space conditions

- Two existing railroad tracks

- An existing truck lane

- Working area existing port crane

- individual customer requirements

- High conveying capacity

- Movable construction

o enable the ship loading to be swiveled, a slewing ring with a diameter of 1.6 meters was installed on the 8-meter-high pipe support on the nacelle.

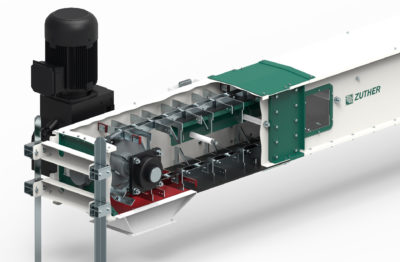

The undercarriage was equipped with rubberized heavy-duty wheels, which have a diameter of approximately one meter. Each wheel has a separate drive unit and allows crossing the tracks. The loading equipment can be swiveled 90° on both sides.

The loading facility has an eight-meter long and extendable conveyor belt. In combination with the driving system or the extendable loading conveyor, we ensure that the ships can be completely filled without having to “fetch” them again. The loading system has a capacity of 525 t/h and thus ensures very economical processes for the operator.

To give the operator as much flexibility as possible, it is possible to choose another way to rail loading via a 560 Zuther folding box.

Even the limitations of the COVID19 pandemic could not affect the completion and did not hinder the trouble-free start-up.

- Individual concept

- Modern running gear system

- Track crossing

- Integrated truck loading

- 1600 mm wide belt conveyor

- 8 meter extendable conveyor belt

- 180° swiveling

- Static calculations of the construction