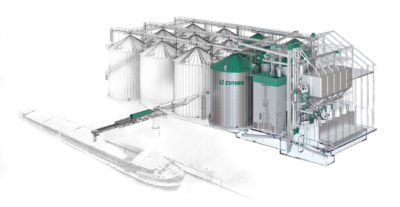

Further plant expansion in the port. A total storage capacity of 65,000m³ has now been created.

The challenge: Pandemic and connection to old plant

In the meantime, the image of the port of Uelzen is characterised by Zuther technology. We were allowed to expand the customer’s facilities in 2014, 2016 and 2020 respectively, and a storage capacity of approximately 65,000 m³ has now been created. There are two plant operators in the port, both of which are mainly equipped with Zuther technology.

Corona as an unforeseen companion

As in many industries, the Covid19 pandemic that was taking hold at the time called for a particularly flexible project team. Due to the official requirements and the tense procurement processes, Zuther had to prove its flexibility and reliability. Thanks to a flexible design of the project plan and excellent cooperation between the different trades, the project was successfully completed.

The challenges

- Tight space conditions

- Connection to the old system

- Connection of the removal conveyors with stock

- Burdens of the Covid19 pandemic

- Assembly and commissioning during port operation

The implementation: 500 t/h silo loading

Silo feeding with a total capacity of 500 t/h*.

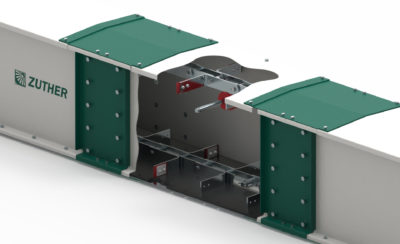

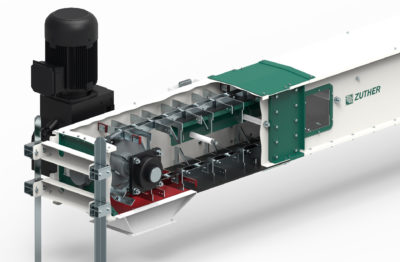

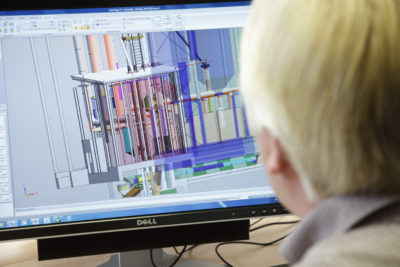

The latest construction phase has a silo feeding system with a total capacity of 500 t/h*. The silo feeding is realised via 2 parallel trough chain conveyors and thus offers the possibility of simultaneous filling via the existing receiving pans. In addition to the conveyor technology, the assembly and the engineering were also part of the Zuther scope of services. Together with the customer, it was decided to make the cellar underneath the silo cells accessible, in order to make the removal conveyors and silo slides optimally accessible. The complete extraction technology, which has a capacity of 200 t/h, as well as the silo ventilation system, were also supplied by Zuther. In order to operate the entire site in a process-optimised manner, a new drying system, including conveyor technology, was also realised and successfully put into operation.

The maintenance for the entire site is digitalised by the service and maintenance software sFIX. We congratulate our customer on the new plant and are pleased that it is well positioned for the future.

The implementation

- Trough chain conveyor

- 2-way loading

- 200 t/h Extraction technology

- Drying plant

- Maintenance by sFIX

- Walk-in cellar