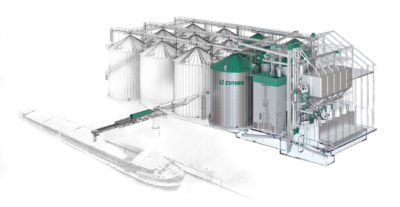

Complete modernization and capacity increase of 21 year old silo plant – including silo cells and entire process technology

The challenge: Disassembly & rebuild incl. power increase

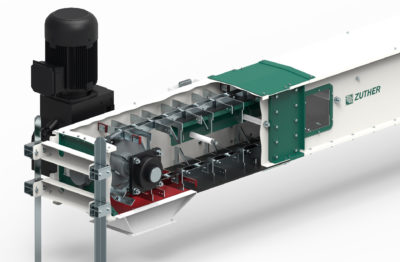

Originally, the silo plant was put into operation 21 years ago. The requirements for the machine technology at that time were different than today. At that time, the trough chain conveyors and elevators fed the four silo cells with a capacity of 150 t/h. In addition, the machine technology was completed by the Optima grain cleaning system and a movable hall distribution system. The plant was operated successfully for almost a quarter of a century.

Capacity increase & replacement of silo cells

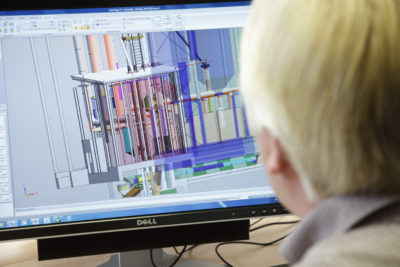

Zuther was commissioned with the modernization of the silo plant and consequently developed a concept to modernize the plant according to the new technical requirements in 2020 and to adapt the processes to today’s requirements.

The project required two challenges: On the one hand, increasing the performance of the existing machine technology and, on the other hand, replacing the silo cells. Due to corrosion underneath the silo supports, the silo cells had to be completely replaced.

The challenges

- Disassembly of the silo cells

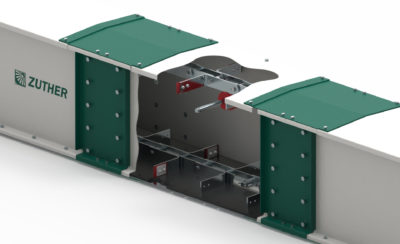

- Disassembly of the conveyor system

- Capacity increase of over 100 t/h

- Burdens of the Covid19 pandemic

- Time pressure due to the harvest

- Assembly and commissioning

The implementation: time pressure & pre-assembly of the conveyor technology

turn old into new – the harvest does not wait

In this project, our project management and the entire installation team proved the quality of their work. Due to the upcoming first, it required a structured project plan, which could not allow any delays. The date when the first deliveries of the new grain harvest would roll into the yard was foreseeable.

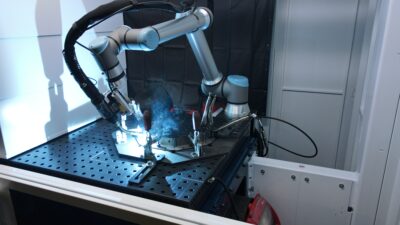

In order to be able to dismantle the silo cells, the existing conveyor technology first had to be dismantled or rebuilt. This was followed by the demolition of the silo cells. New silos with a capacity of approx. 10,000 tons of grain were installed on the old foundations. Due to time pressure, work began in parallel to increase the capacity from 150 to 250 tph. Starting with the bulk material collection, the conveyor technology was pre-assembled so that the final assembly could take place as soon as the silo cells were completed.

We are pleased to have been able to lay the foundation for smooth operation for the next quarter century by modernizing the plant.

The implementation

- Pre-assembly of the conveyor system

- detailed project planning

- Strong assembly team

- Process optimization

- Engineering & Project Planning

- Use of the old foundations