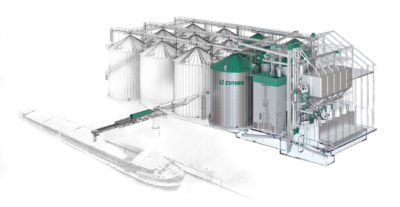

A conveying distance of 400 meters at a height of 12 meters. After the final stage of the project, the conveyor line will consist of six trough chain conveyor lines and will have a total conveying distance of 2400 meters.

The challenge: optimal processes

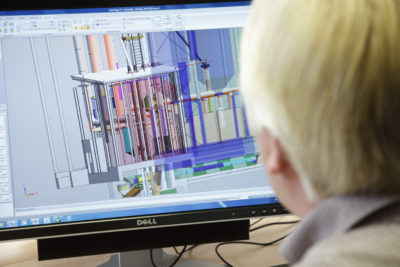

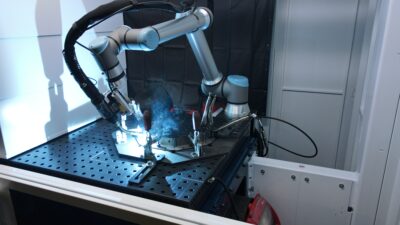

In addition to the entire engineering and assembly, Zuther supplied the complete conveyor technology and steel construction for the project. The engineering was of particular importance in this project, because the aim was to optimize the entire internal operating processes. Another requirement was to maintain the entire operation during the construction work and not to endanger the internal traffic due to the limited space. Thanks to skilful project planning and optimum coordination between the assembly teams and the Zuther plant, the machines could be delivered just-in-time and installed directly.

Process optimization through conveyor line

The task: To connect the newly built granulation system with the different production departments and the silo systems also built by Zuther.

Die Herausforderungen

- Engineering

- Steel structure at a height of 12 meters

- Improvement of internal processes

- Assembly during ongoing operation

- individual customer requirements

- High reliability

- 24 hours operation

The implementation: process optimization through conveyor line

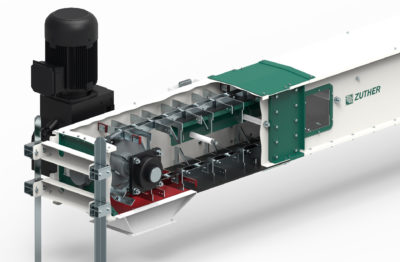

A 400 meter long conveyor line was built. In the first construction phase with two conveyor sections, which will be expanded to six in the next few years. This means that we are installing 2400 meters of trough chain conveyors. The conveyor line connects the pelletizing system with the individual silo systems and production halls. The new conveyor line has made it possible to save enormous operating costs, since the production facilities are supplied in advance mainly by big bags and corresponding transport vehicles.

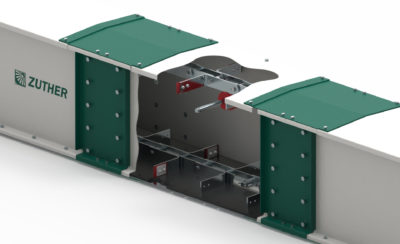

Quality of the conveyor technology – 24/7 operation

Another challenge was the operating time of the machines. The conveyor system had to meet the challenges of a daily minimum running time of 24 hours in three-shift operation. The quality and reliability of the conveyor technology could meet Zuther.

For optimal maintenance and preventive maintenance, our customer successfully works with the service and maintenance software sFIX. Especially with the high industrial operating times, optimal maintenance lays the foundation for safe processes.

Die Umsetzung

- 2400 meters trough chain conveyor

- 400 meter catwalk

- Reliable conveyor technology

- Just in Time – Assembly