Anyone passing through Karwitz on the way to Uelzen will see Zuther GmbH on the right-hand side – a company that, despite its remote location, is an international player in the development and construction of complex plant and conveyor systems. And this in a diversity that is unparalleled.

On all continents, Zuther plants are available for the most diverse areas of application – developed and produced with the most modern digital software and hardware. Computer 3D planning and robot technology are used in all areas of the company. It all started over 100 years ago with the modernisation and new installation of mills.

Processing and conveying have been the focus of the company’s activities since it began over 100 years ago. In 1921, the miller and conveyor company was founded. Anyone passing through Karwitz on the way to Uelzen will see Zuther GmbH on the right-hand side – a company which, despite its remote location, is an international player in the development and construction of complex plant and conveyor systems. And this in a diversity that is unparalleled.

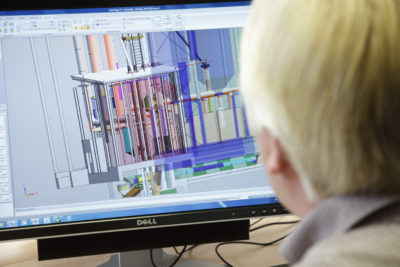

On all continents, Zuther plants are available for the most diverse areas of application – developed and produced with the most modern digital so- and hardware. Computer 3D planning and robot technology are used in all areas of the company. It all started over 100 years ago with the modernisation and new installation of mills.

Preparation and conveying have been the focus of the company’s activities since it began over 100 years ago. In 1921, the miller and the new premises, equipped for woodworking and metalworking, as well as a roller grinding and fluting machine for reconditioning miller rollers, the company was now in a position to considerably expand its product range for milling machines. In 1950 the company moved to Karwitz. In the 1950s, the first cleaning and processing machines for grain were developed. As more and more small and medium-sized mills were closed down in the course of the 1960s, it was decided to focus on another line of business – the development and construction of grain storage and silo equipment. To this day, Zuther has remained a purely family-run business. And-reas Zuther is already the third generation to be active in the business. With his sons Jannik and Jonas, the fourth generation is now also represented.

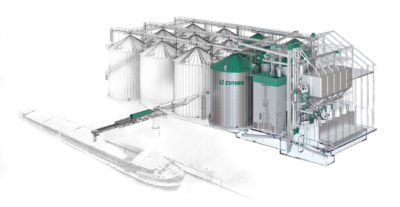

“Today, Zuther is one of the leading suppliers of bulk material technology,” says Andreas Zuther. With the construction of conveying and cleaning technology for various bulk materials, Zuther operates worldwide and across industries. In addition, the company offers a so-called “all-round service” and builds complete plants, such as silo plants. Projects for the Ukrainian sales market, which was only established last year, were, however, made more difficult by the war. “Nevertheless, two projects could be realised during the war”, Jannik Zu-ther is happy and adds: “That is a great success. With a local representation, we manage this market.” Rising steel and energy costs also pose challenges for Zuther. “The current procurement market is very volatile. But we have been able to compensate well for interrupted supply chains so far through our flexible actions,” Jonas Zuther is confident. In the long term, the company wants to further expand Ukraine, which is still the breadbasket of the world, as a sales region. In Russia, on the other hand, the company has stopped sales. But with its broad product range and business activities all over the world, the company remains stable.

Over the decades, Zuther has constantly expanded its know-how in the development of complex plant systems. Among other things, this is also possible due to the very long tenures of the employees. Some of them have been with the company for 40 years. Today, there are 80 employees who plan, develop, manufacture and manage in Karwitz.

Robot-assisted production, computer 3D planning, state-of-the-art application software – Zuther employees can work with the most modern digital planning and manufacturing equipment. Exciting and diverse is then also the training in the company. “We place a lot of value on our own apprentices,” says Jannik Zuther. “After all, they secure the future of the company,” adds Jonas Zuther. Four to five young people can start an apprenticeship in the company every year in four professions so far: Industrial clerk, technical product designer, construction mechanic and warehouse logistics specialist.

At Zuther, the future clerks learn how paperless administration works in addition to the diverse commercial activities. Due to the digital processing of most tasks, working in the homeofffice is no problem for the company. Those who train as technical product designers not only learn about the planning and development processes, but also how to work with state-of-the-art digital tools. In the case of construction mechanics, in addition to the manual work, the main focus is on learning how to use the robot technology that is used to control production. In both professions, the company also enables further qualification as a master craftsman. Last but not least, the company also offers opportunities to those who want to train as technicians or business economists in dual studies.

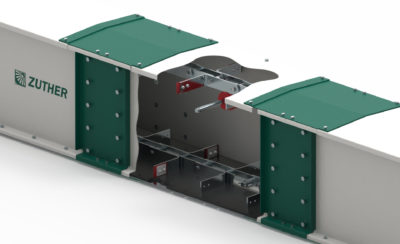

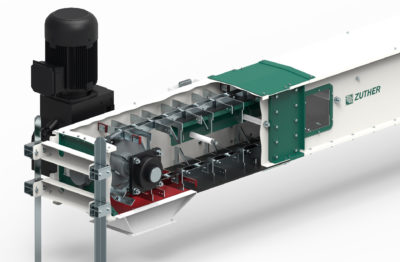

The example of grain delivery and storage shows how complex the tasks are for which the technical product designers and construction mechanics at Zuther have to find solutions. “This can be particularly exemplified by our silo systems, which are very complex,” explains Jannik Zuther. After unloading the lorries via the corresponding receiving trough, the grain is dried and processed if necessary. Processing means cleaning or classifying the bulk material. The good quality of the grain is the basis for smooth storage in the silo cells. An effective dumping and weighing system is necessary for transport. The grain is then loaded by ski or truck. In order to be able to control and monitor the entire process, a measuring and control system must also be integrated, which implies an hourly output of up to 800 tonnes per hour.

For trainees and employees, these complex processes mean that the knowledge and skills they acquire at Zuther can be used in many industries. Excellent opportunities, therefore, for Zuther trainees on the entire labour market.One particular key qualification is not so much taught as lived in the company: flexibility. Since the company is active in different areas – agriculture, stone and earth or industry – this means that the employees have to adapt to new challenges every day. After all, a conveyor system for hot road asphalt – where Zuther plants are often used in Germany – has completely different requirements to consider than a conveyor belt in a gravel plant.

Planning, developing, buildingIn Karwitz, we not only plan and develop, but also produce. In addition to “all-round carefree plants”, customers can also obtain plants for individual operations such as pouring, loading and drying. Furthermore, Zuther also undertakes contract manufacturing in the metal sector. Laser cutting, pipe plasma cutting systems, or robot welding – Zuther employees have experience with a whole range of the most modern production systems, some of which are highly automated. The finished systems are delivered in transportable individual parts. When police cars with blue lights roll off the premises at night, then once again a heavy goods transport from Karwitz is on its way to a construction site, because individual modules such as elevators sometimes take on dimensions that make transport in daily road traffic impossible. Last but not least, Zuther also offers a service for the assembly and maintenance of the complete systems. For this purpose, a software was specially developed: the intuitive maintenance software sFIX, developed in the company, with which the maintenance and documentation of the operation of a complex industrial plant can be carried out digitally and the maintenance costs can be reliably reduced.

Those who work at Zuther work on demanding projects with a wide variety of requirements. Modern production with extensive use of computers and robots makes working at the company attractive – and future-proof. Solid craftsmanship is also a reason for the high quality of the products. “It is this combination of tradition and modernity that sets us apart from others,” says Jannik Zuther: “Quality from tradition is our motto.”