×

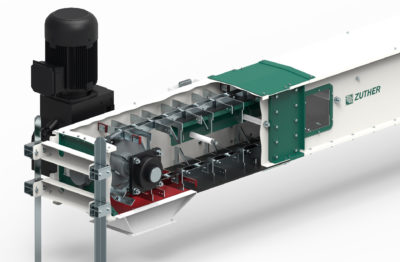

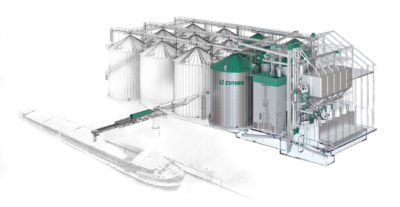

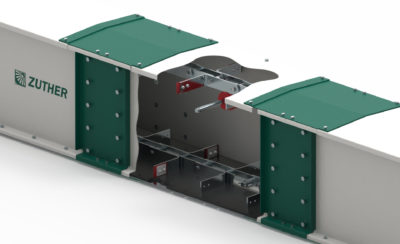

Conveyor technology

Cleaning Technology

Pipe system

Dedusting system

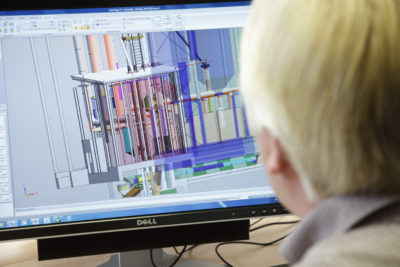

System control

×

×